model SWR is equipped with a safety function, which is called a self-locking function, that prevents a hand/tool from falling when air pressure is cut off in case of emergency.

This function is for emergency such as blackout and cable disconnection, etc. Make sure to supply lock air pressure during normal operation.

Basically, model SWR cannot be installed to a robot directly.

Because mounting flange dimensions are different depending on a robot, it is required to install an adapter plate (spacer) between a robot flange and SWR.

For robot flanges based on ISO, we offer an optional adapter plate (model SWRZ).

Check the following video installing an adapter plate and SWR to a robot flange.

Please refer to SWR-M□ Mounting Bolt Reference List for recommended mounting bolts for model

SWR-M which is installed to the robot side.

For the tool side, please select bolts based on thickness of bolt hole part of a hand/tool by customer.

※ Mounting bolts are not included in model SWR. They should be prepared by customer.

A lift up function is a knockout function to securely detach a hand/tool when connection is released.

The lift up function prevents overload and damage that are caused by a robot interfering with a locating pin on a stocker side, unable to be detached when releasing (disconnecting) a hand/tool.

During connection, a seating surface and locating part are protected by the lift up function that makes a gap between the robot side (master side) and the tool side of Robotic Hand Changer (model SWR). This gap before connection also helps a secure connection check with seating air and an effective air blow.

Reference for automatic robotic hand/tool change and robot teaching.

CLICK to see >>> "SWR Teaching Example"

In case robotic tool change is not so frequent that you want to change hands/tools manually:

CLICK to see >>> "Control SWR with Manual Air Valve"

Please refer to the following video.

※ When an operator is close to a robot during robot operation, make sure the robot is in an emergency stop state.

※ The robotic hand in this video is light, and operated after safety is ensured. This method must not be done when safety is not ensured and in the environment with a heavy workpiece, high temperature, fire and electrocution, etc.

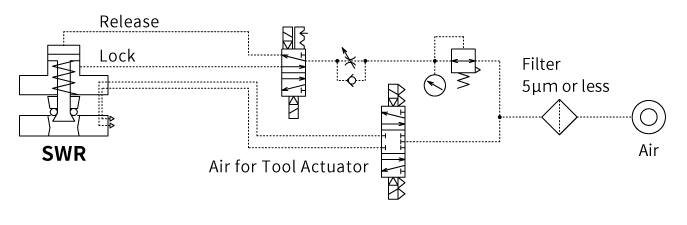

During normal use, make sure to supply air pressure to the lock circuit.

Even if the air pressure becomes zero due to power failure, the self-lock function with a spring prevents the tool from falling.

【When using a 2-Position Solenoid Valve】

Please use a 2-position double solenoid valve. In case of using a 2-position single solenoid valve,

for safety, connect the piping so that air is supplied to the lock side when the power is turned off.

If air is supplied to the release side, it is dangerous as it may cause the tool (hand) to drop. Also, in the case of 2-position single, please note that if the power is turned off in the release state, it will lock.

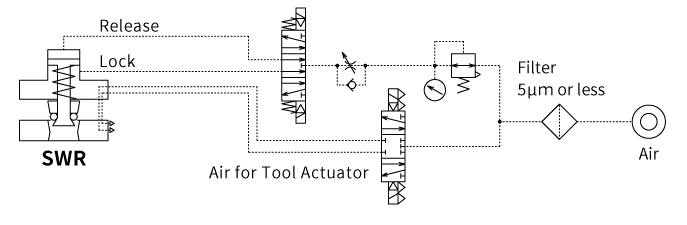

【When Using a 3-Position Solenoid Valve】

Please use the valve with a 3-position exhaust center. When the power is turned off due to emergency stop, please be aware that the robotic hand changer will perform locking operation even in the released state due to the fall prevention function.

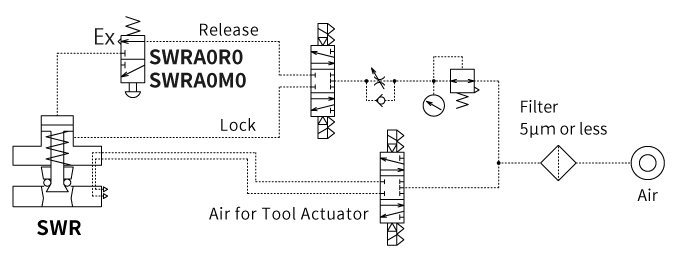

【When Selecting Other Valves】

When using a 3-position closed-center solenoid valve for controlling the robotic hand changer,

which is the same as the tool actuator, please use the fall prevention valve (SWRA).

※ SWRA0R0 Fall Prevention Valve

It supplies air to the release side only at a designated position.

Refer to our product page (model SWRA) for detailed specifications and cautions.

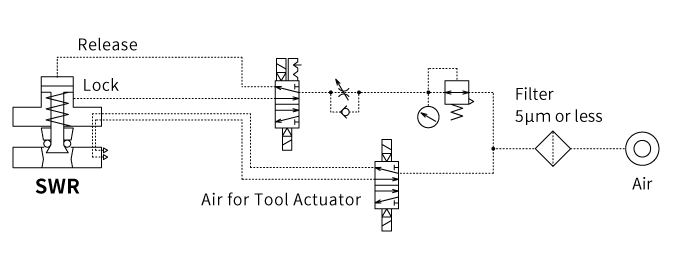

【Solenoid Valve for Tool Actuator】

When using a 2-position solenoid valve for the control valve of the tool actuator, select the check valve option (SWR-S) of the robotic hand changer.

Please check the following page.

>>> "Comparison between SWR Standard Model and Check Valve Option"

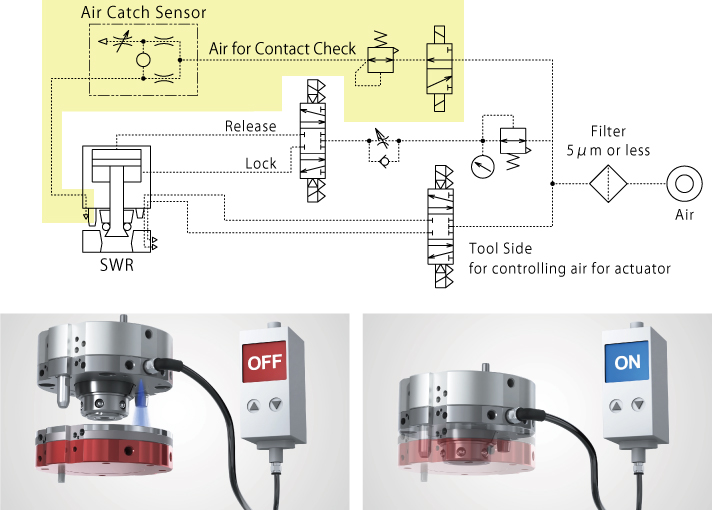

The connection of SWR can be confirmed by connecting an air sensor to the SWR port option F: with seat check port (standard). There will be air leakage when seating surfaces are not in complete contact in a connected state.

■ Reference Circuit Example

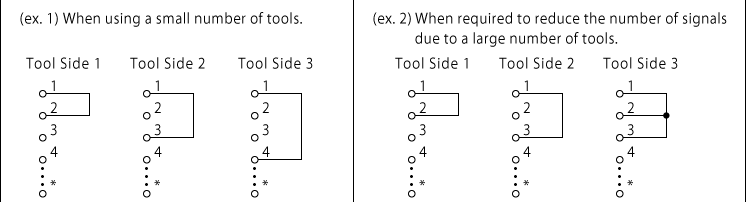

Tool distinction with a robot controller and PLC is possible by using an optional electrode and differentiating short circuit points of the electrode depending on a tool.

※ If necessary, please provide a load.

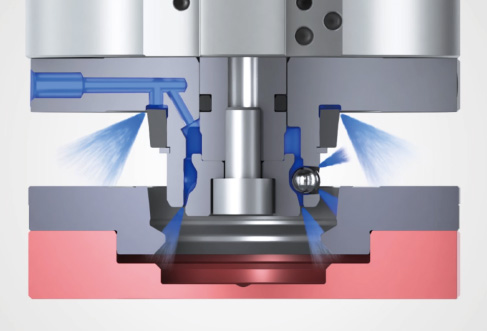

We offer model SWR with air blow port (option symbol A).

Air blow by supplying air to the port prevents coolant and other contaminants from entering into the product.

We offer a variety of electrode options for model SWR, including waterproofing options (see below).

For further information, please refer to the product catalog.

- W:Compact Waterproof Electrode (Non-contact Electrode) Applicable to IP67

Number of Signals:4 (Input Only) - V:Waterproof Electrode (Non-contact Electrode) Applicable to IP67

Number of Signals:12 (Input Only) - U:Simple Waterproof Electrode (Equal to IP54 only when SWR is connected.)

Number of Electrodes:16 ※ The simple waterproof electrode seals the outside perimeter of the electrode only when SWR is connected. When disconnected, the electrode part is exposed, so please consider the operating environment.