Designing and Teaching Tips for Automating Robotic Tool Change

with KOSMEK Robotic Hand Changer (model SWR)

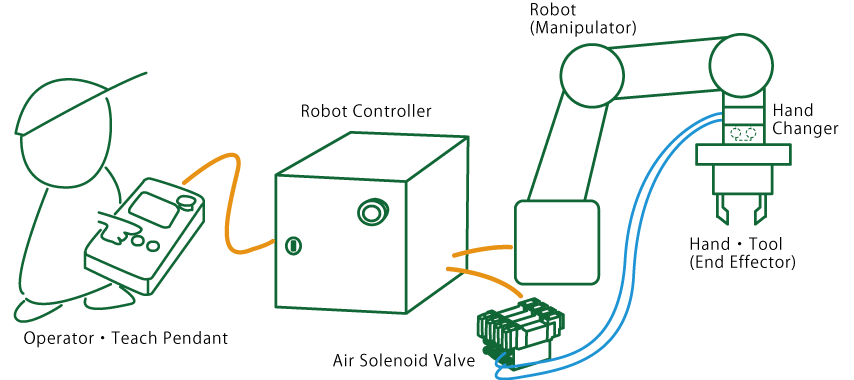

A human operator uses a teach pendant to operate a robot (manipulator) and store positions and commands in a robot controller. This is called “teaching”. The robotic tool changer (model SWR is a pneumatic double acting device) connects (locks) and disconnects (releases) by operating air solenoid valves with external output of a robot controller. Solenoid valve can be set to the suitable position: on a robot end, outside, or inside a robot.

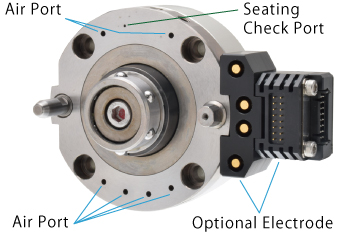

model SWR0120-MF-JK

An actuator of a hand, deburring tool, suctioning tool, sensor, camera, welding gun and others can be installed to a robotic hand/tool.

Kosmek robotic hand changer (model SWR) enables air and electric supply to a robot via its air ports and optional electrode.

Kosmek robotic hand changer (model SWR) enables air and electric supply to a robot via its air ports and optional electrode.

The video is not working? SEE IT FROM HERE>>>

This video introduces the teaching method and tips of SWR.

The following is the designing and teaching tips of SWR.

- Do not completely fix a robotic tool on a stocker. A robotic tool should not be completely fixed on a stocker. There should be some gap between a locating pin and a hole for setting the robotic tool to the stocker. The amount of gap should be within “Allowable Offset while Teaching” written in the SWR catalog.

- Shut off power supply to an electrode. Please shut off power of an electrode during connection and disconnection. Failure to do so leads to continuity failure.

- Make an adequate gap during connection and disconnection.

An adequate gap prevents excessive load to a robot and a stocker during connection/disconnection.

It is explained in the video as follows: “There is an enough gap if you feel a slight move when shaking a tool.”

【During connection】 A gap between contact surfaces, where the end of SWR (lift-up part) touches the tool side, should be within 0 – 0.5mm.

【During disconnection】 SWR detaches a tool with lift-up function. A gap between the tool and the stocker should be more than lift-up amount (detaching amount) written in the SWR catalog. If necessary, set a cushioning function between the tool and the stocker. - Do not move a robot right after an output of connection/disconnection command. At the time of connection/disconnection command, an electric command is completed within a second and the robot continues to the next program, however, increasing and decreasing of air pressure take some time. Make sure the robot moves after air pressure completes increasing/decreasing, or perform action confirmation with a sensor.