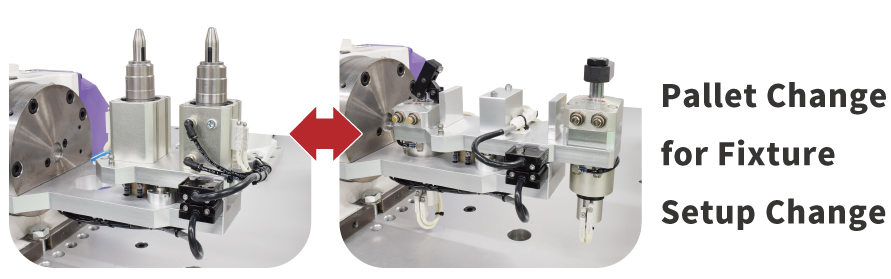

With products for pallet change, pallet locating between processes becomes highly accurate and setup change can be simple and quick.

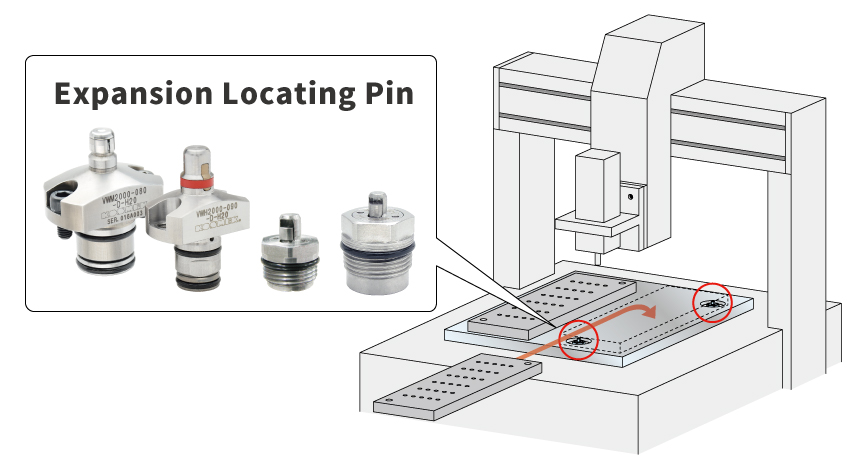

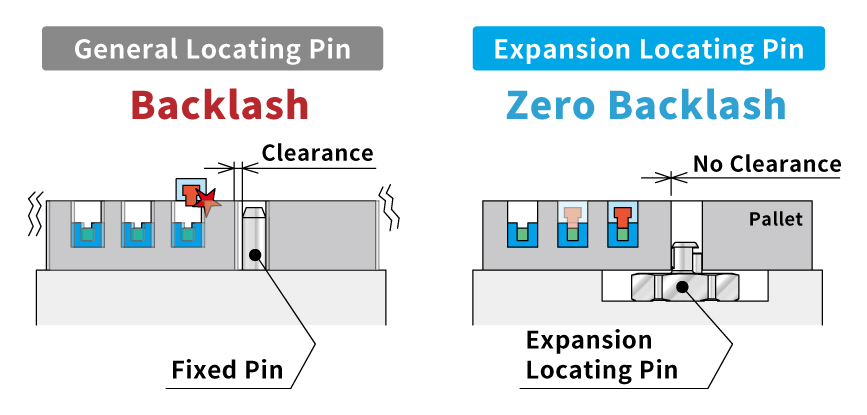

Introducing a locating method when no load is applied to a pallet, or no clamping force is required such as for a testing device or a spraying device. Locating is possible if a pallet has holes (when a connecting block is not preferred).

I.D. gripping of pallet holes with “Expansion Locating Pin” enables high-accuracy locating.

Expansion locating pin has no clamping force, but a pallet can be located when a load is less than the expanding force.

We have a wide variety of expansion locating pins. Please refer to the product line-up for further information.

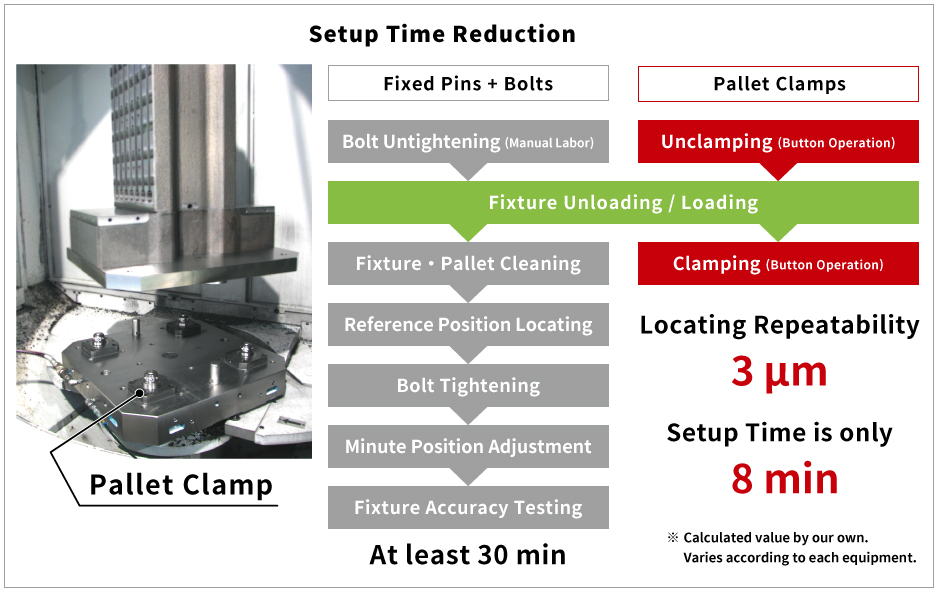

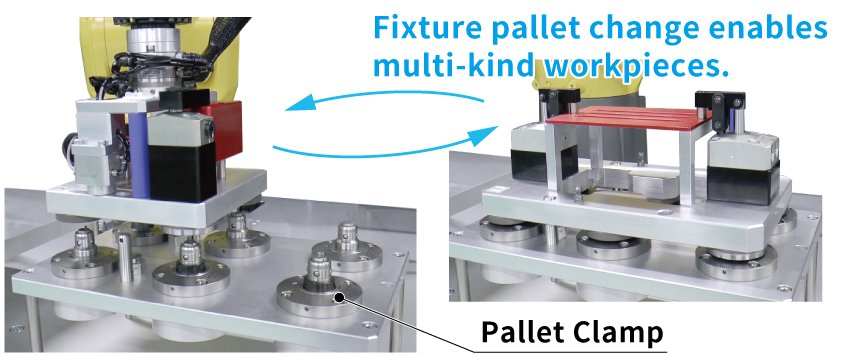

By using pallet clamps, anyone can change pallets with high accuracy and reduce setup time.

Unlike bolt tightening, pallet clamp enables fixture change in mere seconds.

Moreover, locating accuracy is higher than the previous locating method using edge locators and locating pins.

The following shows the comparison between the previous method: locating with edge locators and clamping with bolts and our solutions: Pallet Clamp. Setup time is reduced, and locating accuracy is improved.

Moreover, no skills are required and labor can be reduced for more safe operation.

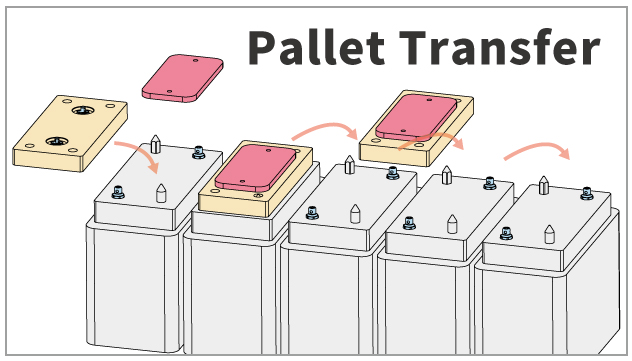

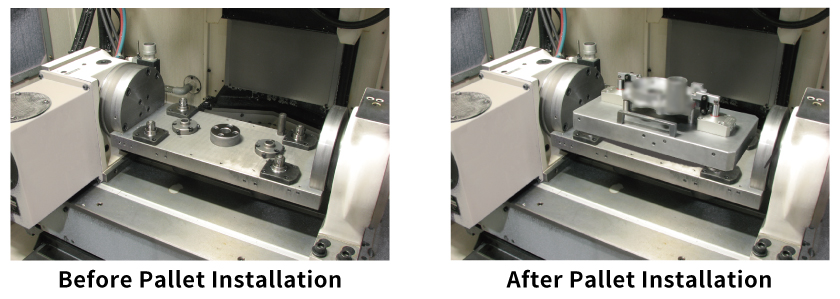

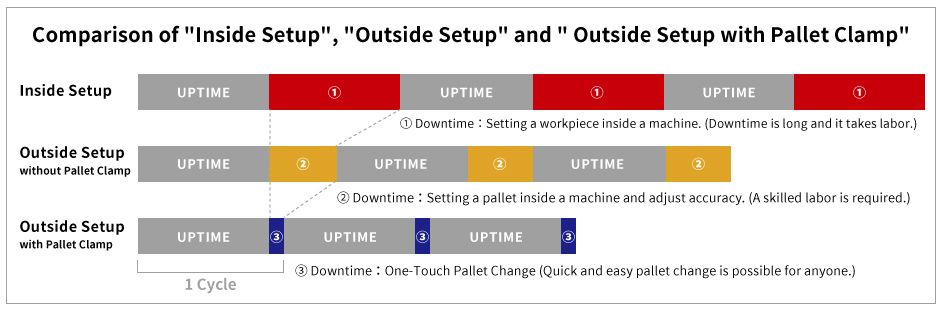

In order to extend uptime of machines and equipment, downtime has to be as short as possible.

For that, “outside setup” - to prepare a workpiece on a pallet beforehand and outside the machine - is a solution.

Outside setup leads to downtime reduction, but an operator has to be highly skilled when mounting a prepared pallet into a machine to adjust its position precisely.

However, using a pallet clamp enables anyone to perform high-accuracy locating and clamping easily. Pallets can be exchanged in a short time, reducing the machine downtime to the utmost limit so that productivity will be increased.

The above ③ is the time (downtime) when changing pallets by using Pallet Clamps.

Compared with ①②, machine downtime is drastically reduced.

Please refer to the following video for pallet clamp changing operation.

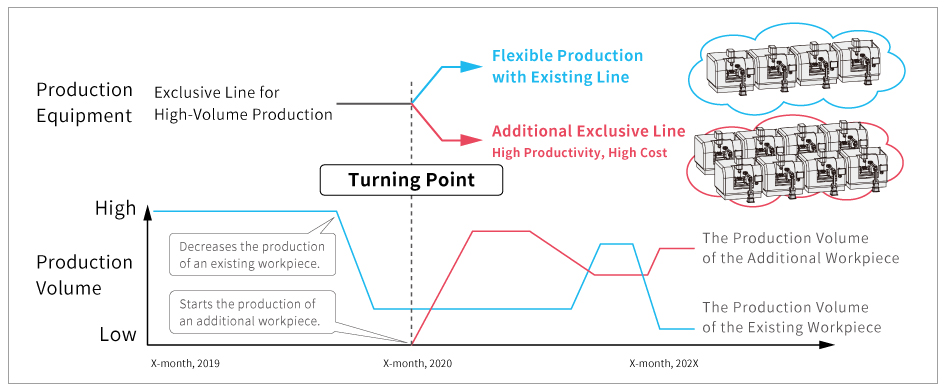

Pallet change makes a production line flexible and mixed, reducing cost for investment.

The above shows the image of reduction in initial cost by using the existing production line whose production amount is decreased for a new workpiece. More automation is possible by using a robot for pallet change.

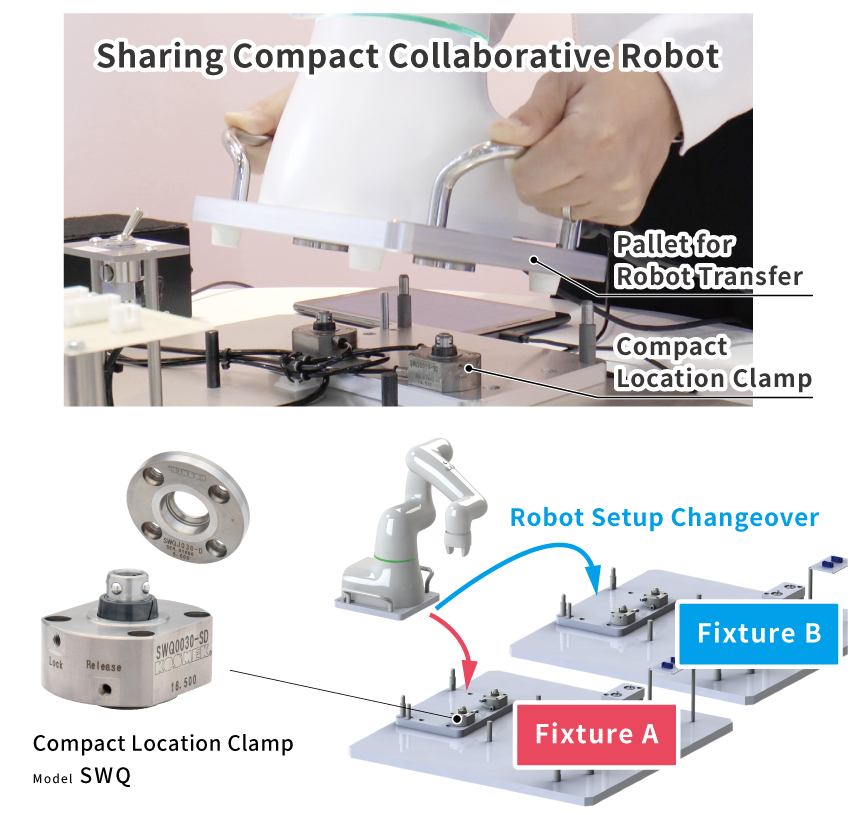

When a robot is changed among several processes, Location Clamp (model SWQ/SWT) with 3μm locating repeatability will eliminate re-teaching of the robot or correcting its position.

Setting can be done easily by anyone.

A single robot can be used for both "Fixture A" and "Fixture B" that have different operations. Transfer and setup change of the robot generalize operations.

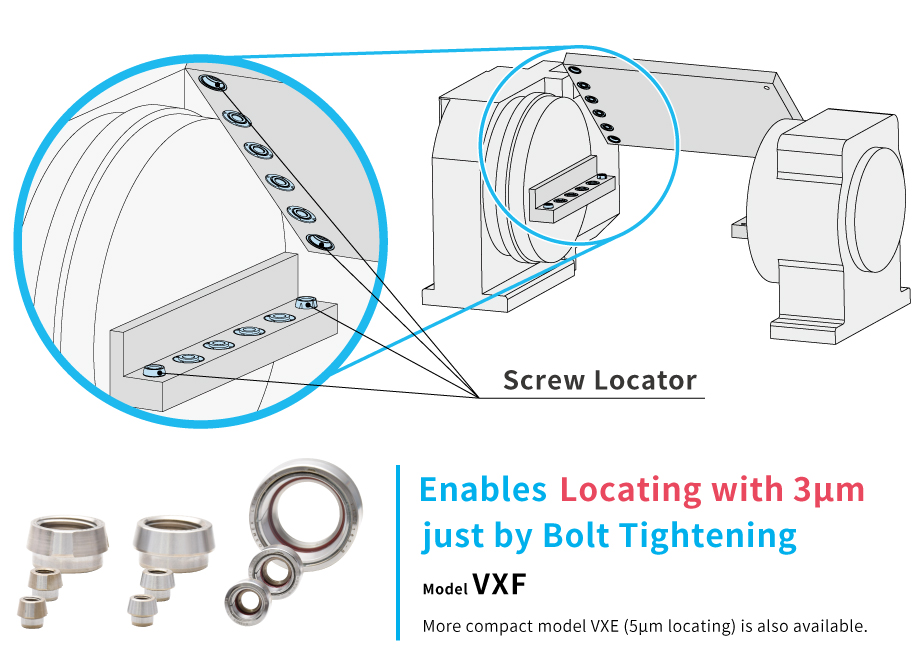

For those who want to change pallets with high accuracy without large investment because setup change is not so frequent and prefer manual setup improvement for the first step, we offer “Screw Locator” that is used as a manual model of Pallet Clamp.

Screw Locator enables easy and quick high-accuracy locating just by bolt tightening.

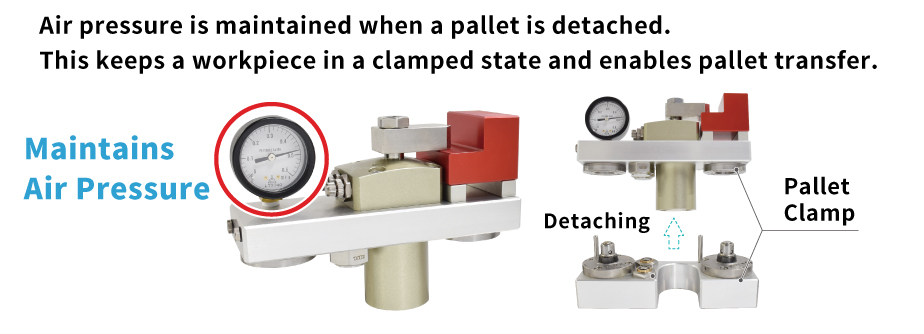

To transfer a pallet to the next process with a workpiece in a clamped state, holding air pressure in the pallet side even when the pallet is detached from the fixture plate: “Leakless Coupler (model JWC/JWD)” enables to maintain the air pressure of the air actuator on the pallet even when the pallet is detached from the air source.

>>> See the Product Page (model JWC/JWD)